Guitarists often go to great lengths and expense in their quest for the ultimate guitar tone. Yet speakers all too often get overlooked. So long as they make a noise they are good right?

Actually, there are many potential problems a speaker can have, from voice coil rub to a torn cone, all will have a negative impact on your tone.

Here is my simple 4 step process to assess the condition of your speakers:

1. Check all glued areas

2. Inspect cone condition

3. Check for voice coil rub

4. Assess sound quality

To perfom all 4 tests should only take a couple of minutes per speaker and they are all super easy to do. Apart from the sweep test (optional, but highly recommended), all of these tests can be done with just your bare hands, eyes, ears, and the gear you likely already own as a guitarist. No excuses!

Step 1) Check all glued areas

There are 3 important glued areas on a speaker; the edge of the spider support, the edge of the dust cap, and the outer edge of the cone. For a speaker to function properly and sound ‘right’, all of these areas need to be 100% fully glued down.

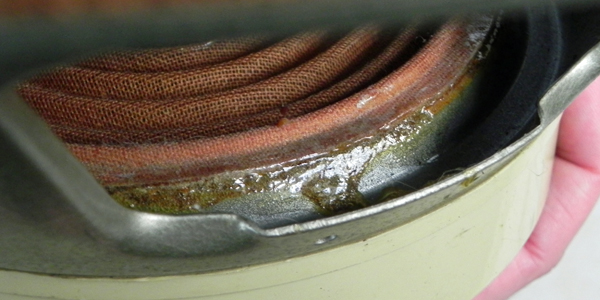

Spider Support

To check the glue at the spider support, lightly brush your finger tip against the edge in an upwards motion to check it is still holding. Work all the way around the edge, bit by bit.

It is always tempting to do this in a ‘half arsed’ way, so time yourself. To check it properly should take a full 60 seconds per speaker minimum. Be as thorough as you can.

Use your ears as well as your eyes. Very small areas of failed glue may not be visibly obvious, but if the glue is not holding you will hear it as your finger brushes against it, as in the video above.

Failing glue at the spider support is probably the most common fault to find on old greenback speakers. Therefore it is very important to check, and is always the first thing I look for.

Also watch out for sloppy amateur repairs. A bad repair done with super strong modern glue is often irreversible and the speaker could be ruined with permanent coil rub if the voice coil has not been re-aligned properly.

Cone edge and gasket

Check the cone has not been torn off, or become unglued, at the outer edge. This happens more often than you might think. It is usually caused by someone trying to pull a stuck speaker out of a cab with brute force. The gasket stays stuck to the baffle while the cone rips off.

Brush the edge of your thumb against the gasket in an upwards motion to make sure it is still holding all the way around.

When removing speakers from cabs, always make sure they are free from the baffle 100% before trying to lift them out. Use something thin like a feeler gauge to work underneath the gasket and unstick it from the baffle.

Dustcap

Gaps in the dustcap glue are fairly common and will cause the speaker to buzz. This is not usually a serious problem unless dirt has gotten inside the speaker causing voice coil rub. To repair a dustcap like this neatly, it is best to carefully remove the whole thing and reglue it back on.

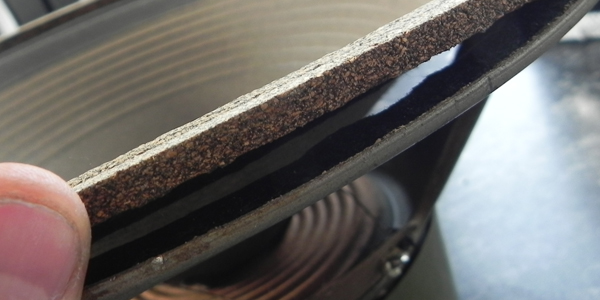

Step 2) Assess the condition of the cone

The condition of the cone is important because it will have a direct impact on the quality of the tone it produces.

The best sounding cones are usually the ones that are still near mint – firm to the touch and blue/grey in colour. Cones in poor condition that have gone very brown and soft, had severe repairs, or flood damaged, will usually sound the worst – if they are even fit for purpose at all. However, I do think it is important to let your ears have the deciding vote, some speakers can surprise you!

Also watch out for small tears forming at the outer cone edge, and along the rear of the cone. This is usually the sign of a well used speaker:

Step 3) Check for ‘voice coil rub’

There are many reasons why a speaker can have voice coil rub. From a bit of dust in the coil gap to more serious problems such as a damaged voice coil or a shifted magnet.

To check for voice coil rub you need complete silence, so find a quiet room and switch off any background noise. Then put the speaker on its back, preferably on something soft like a folded blanket then you don’t scratch the plastic cover when rotating it.

The resting position of the cone is roughly the halfway point of its full movement. So it is important to test both the inward movement, and the outward movement.

Check inward cone movement:

Press lightly down on the edge of the cone with both of your hands touching at the index finger, and then let go. Repeat this about 6 times so that you “pump” the cone in and out, slightly off its normal axis. Do not press hard, just use a light pressure.

It should be a completely silent movement. Any scraping or clicking sounds are bad!

Bored already? There are videos demonstrating this process further down the page 😉

You need to do this all around the front edge of the speaker cone. So turn the speaker an inch or two and repeat. The way I usually do it is to imagine the front of the cone cut into 8 sections like a pie, and perform the test in each section. Use the screw holes as a location guide.

Check outward cone movement:

Do a similar thing again for the outward movement. This is a bit more awkward because the chassis legs will be in the way, so you will only be able to do it at 4 locations.

Place your finger tips under the chassis about mid-way up the cone, and press upwards using light finger pressure. Then turn the speaker and repeat until you have done it on all 4 sides.

Again, this should be a silent movement.

How not to do it

Most people check for voice coil rub by pressing directly down on the cone only, not around the edge as shown above. This is nowhere near a sufficient test in my opinion.

Speakers can still sound really horrible and pass that test. Don’t ask me why, but I can only assume that the voice coil vibrates a fractional amount horizontally too when in use. If you watch all the videos on this page you can see this being demonstrated.

I also think it’s important to check the full range of motion of the cone. So always check the outward cone movement as well as the inward cone movement.

Find ‘benchmark’ speakers for comparison

If you’re not sure if you are performing these techniques correctly or maybe just think I am talking a load of nonsense, then for comparison try them on a modern speaker that you know to be perfect. That way you have a ‘benchmark’ for how a good speaker should test. Ideally use a speaker that has been well broken in and has good cone movement.

Likewise it is a good idea to keep a known bad speaker around so that you have an idea how a bad speaker tests. Eg how loud you need to play before the coil rub makes itself known. Every speaker is different of course but having some benchmark speakers to hand will definitely help you when first starting out testing speakers.

Step 4) Assess sound quality

Ideally you first want to test your speakers with an audio generator to listen out for faults, and then with guitar and amp to assess the quality of the tone. However if you don’t have the equipment you can probably get away with just one method or the other.

Click here to skip to testing with guitar and amp.

Test 1 – using an audio generator (sweep testing)

If you do not own a sine wave audio generator, don’t panic, there are various free apps around thesedays such as www.synalski.com tone generator that you can use instead.

If you want to buy an audio generator, check whether it has a good frequency display or not. To match frequencies with the notes on your guitar, you will need to know what frequency you are at.

If you’re interested in what gear I use myself, I had a ‘Tenma 72-455A’ for many years and can recommend them. However I am currently using an older ‘Trio AG-202A’ unit.

One thing you will definitely need is a suitable amplifier. Ideally transistor then impedance matching is not an issue. Also you do not want to kill your speaker. Something that puts out about 15 to 20w is ideal for testing old greenbacks.

Remember that transistor amps only put out their highest power rating when used with the minimum speaker load, usually 4 Ohm. So a 100w amp into a 16 Ohm speaker will probably only be putting out about 25w, I’m reliably informed. However do not risk it and fully dime the amp. Just have it loud enough to get the speaker cone visibly moving.

The amp I am using right now for speaker testing is an old Laney 80w PA with a minimum impedance of 4 Ohm. So in theory, that puts out around 20w with a 16 Ohm speaker.

How to do it

Lie a single speaker on its back, preferably on something soft to cushion the vibrations, then connect up to your audio generator and amp, and power on.

With the frequency dial on the lowest setting (10Hz on mine) turn the volume up. Most speaker problems do not reveal themselves at low volume, so give it plenty of power, but not so much that you are going to blow the speaker.

At 10Hz the cone will start bobbing up and down through it’s full movement. You will learn a lot about your speaker just by running it at 10Hz like this. You should only be able to hear a slight purring noise of the cone moving. Any rubbing, scraping, rattling, or clicking noises are bad!

Next, slowly turn the dial up through to 100Hz and listen out for rattling, buzzing and distorted overtones. A speaker without any issues, and that is nicely broken in, should sound nice and smooth as you move up through the frequencies.

A low frequency sweep like this will weed out 99% of coil rub and other speaker faults in my experience, without needing to sweep the higher frequencies.

To check for cone cry on the higher frequencies I prefer to use guitar and amp (see next test below), because the high frequencies on an audio generator can be very painful on the ears.

About “Cone Cry”

Cone cry can be described as an additional ghost note or an unwanted harmonic. Usually heard whilst bending notes on the guitar.

Pretty much all vintage speakers will have a small amount of cone cry somewhere when tested with an audio generator. Unless the issue is particularly bad it is not something I would worry too much about.

However, if you do find any very troublesome frequencies or severe cone cry, then it is always worth trying to replicate that frequency with your guitar just to see how noticable the issue is ‘in the real world’.

To do that you will need a reference chart like this one to match the note on your guitar to the frequency displayed on your audio generator:

Test 2 – using guitar and amp

You don’t want to overheat your vintage greenback so choose an amp around 15w to 20w that you can run into a single speaker. I’m currently using a Marshall SV20H, but for many years I used an Orange Tiny Terror.

How to do it

Lie a single speaker on its back, preferably on something soft to cushion the vibrations, then connect up to your guitar and amp, and power on.

It is best to use a fairly clean tone, or just on the edge of break up. Too much distortion, or other effects, can mask any sound issues with the speaker.

Get loud! As I mentioned earlier, most speaker problems such as voice coil rub will not reveal themselves at low volume, even severe cases. Also, in my opinion speakers only show their true tonal characteristics when they are made to work hard. Find the sweet spot. My rule of thumb is that if you cannot visibly see the cone moving up and down whilst you are playing then you are probably not playing loud enough. Get it really pumping!

To check the speaker properly you should really do a full chromatic run (play every note) from the low E note (82Hz) to the highest note on your fretboard. Some speaker issues will only reveal themselves when you play certain notes, so try to cover them all, especially if you have skipped testing the speaker with an audio generator. This is the next best substitute.

It doesn’t have to be completely boring though. Have some fun and have a bit of a jam all over the fretboard. Play some power chords and palm muted ‘chugs’ to check the lower frequencies. Check the mid frequencies with some double string bends around the 8th to 12th fret, and check for cone cry in the higher frequencies with some single string bends high up on the fretboard.

Just generally have a bit of fun and listen to what your ears are telling you. Some speakers will disappoint you and some speakers may surprise you. That is all part of the fun of vintage gear. Keep experimenting until you find the really great sounding gems!

Excellent article, I’m bookmarking it for future reference.

This whole website is a goldmine for Speaker info.

Thank you very much for this Brian.

Author

Hi James, many thanks, glad you like the article.

regards, Brian.

Thanks Brian. I learned so much the past to day, where I have been actively bidding on “the bay”. Though I give a comment on one of the clips, I will mention it here too. I am new to the international community of websites selling speakers, preferably pulsonic Greenbacks and I want to share: don’t be too eager when bidding or buying. Really check the pictures even ask for more elaborated pictures for the sellers before bidding.

It can really be a problem or a drag to withdraw a bid or a pain in the 💥 to return a bought item, because of male functions.

Best regards Steffen

Author

Hi Steffan, good advice. When I am buying speakers on ebay, if I can’t view them in person before making payment, I will often ask the seller to do a full coil rub check and spider support check as shown on this page. Better any problems are spotted whilst in their hands than in mine. The dispute / returns process on ebay can be long and horrible, not all sellers are the friendly type!

regards, Brian.

What I don’t understand is you can hook up an audio generator and not make any noise? In your video with you passing frequencies all I heard was the speaker vibrating.

I left you a comment on youtube, I got four basically new but used speakers , 2 make a scraping sound when I lightly press on them. For me to reveal coil rub I’m assuming I’d have to really blast my amp. I was at 90 db at the master under 2. I wasn’t even moving the cone at that volume . Atleast I could tell from behind the amp (open back)

I called some amp techs and they told me it was ridiculous to press on the cone, I asked them if they could run it With an audio generator to properly test it for me since I wanted to test it properly. I can’t totally blast it at home and I don’t want to assume it’s fine ( because I wasn’t able to fully blast and test it ) then play with a band or record loudly and then realize I have issues with the speakers .

No one seemed willing to help me. All I managed to do was create more tinnitus for myself . I was fine before .

Who knew it would be so hard to pay someone for their help . I’m really not trying to blow my ears out to test it to that level. In a band I’d be protecting my ears and also in a recording situation, if I take over a hundred db to the face when I could do it some other way then it seems more logical and safe to do it was a generator

Author

Hi Nick, yes an audio generator will be quiet at lower frequencies from about 10hz to 30hz then they become gradually louder as you move up into the speakers frequency range. If you cannot run a guitar amp into the speaker at high volume, it might be worth investing in one. Because the cone is moving up and down deeply at low frequencies it tends to reveal any serious coil rubbing straight away whilst not producing much sound. This is the beauty of them.

Please don’t go crazy with your amps volume level and give yourself tinnitus. What amp are you using and what are the speakers you are testing? Are you testing the speakers individually or running them all at once?

You only want to play through one speaker at a time. This is a lot quieter than playing through two or four speakers at once and requires less power from the amp to push the speaker. Also you only want to use a low powered amplifier, something 15 to 20w. I used an orange tiny terror for years. Not the best sounding amp but is fine for testing a speaker. You don’t need the amp to be fully dimed, but as loud as you can bear. Face the speaker away from you, and stand well back from it. Wear ear protection if you need to.

Then you just want to listen out for unwanted rattling or buzzing from the speaker, or any other nasty noises that might be there. If it sounds good – it is good. Try to cover the whole fretboard but playing some bassy power chords in particular will usually reveal any coil rub.

Playing through the speaker like this is ‘king’ over all other testing methods in my opinion. So if you have speakers that sound good when played through, but are a little scratchy when moved by hand then do not worry about it. How they sound when you play through them is what matters the most.

Moving the cone by hand is a well known method for checking speakers if you look around online. I would be interested to know what your amp techs recommend as an alternative. But yeah, everyone has their various methods for testing speakers. I think a lot of those are nonsense personally, and will usually only tell you if the speaker is dead or not, rather than if the speaker sounds good or not. Attaching a battery, attaching a multimeter, flicking the cone, playing a radio through it a low volume. Vintage amp dealers will normally use those methods so that they can write in their selling description that the speaker has been tested and “works great”. All they really mean is that the speaker isn’t dead!

Bear in mind this article is mainly aimed at vintage greenback speakers. Vintage speakers are a lot more prone to having issues than modern speakers. The materials used for building speakers thesedays such as the glues are a lot more robust than they were back in the 60’s and 70’s. So a modern speaker that has been used with care by all previous owners is a lot less likely to have any problems, and will usually be fine.

Hope that helps anyway,

Brian.

Thanks for the quick response . Yeah the techs didn’t give me an alternative aside from saying I’m over thinking it and to just play it. But I explained to them my certain limitations , I was told they almost never have heard issues of fine cry or coil rub and that most people don’t even know what that sounds like . And that he couldn’t Just test the speaker free floating in air and needed it to be in the cab.

But I got these speakers for an extension cab I would get built so I don’t have a dedicated cab so I did offer to put it ok my blackstar ht club 40 since it’s lower wattage . I do also have a 10 watt blackstar but figured that’s not enough wattage to drive the speaker .

The slight issue is the blackstar is 40 watts and these speakers are 30 watts.obviously the issue here is I can overdrive the speakers with that rating . So they aren’t vintage, they are heritage g12h30 55 hz speakers , but Iv seen many videos use similar techniques for more modern speakers in diagnosing coil rub .I got them used and the person I bought them from said they were only used for a single recording . I considered maybe they blasted them in their amp possibly and didn’t take care of them possibly . Two of the four I got had that scratchy issue . And another 4 speakers I have, I also tested by hand and none had this issue of scratchyness.

My issue was when I was playing loudly I looked at the cone and didn’t see any movement . So Im confused as to how hard is hard enough to push it . Even near a hundred db I didn’t see any pumping, but maybe it would be hard to see that from behind , I was looking at the cone easily but it was still it seemed .

I spoke to another guy who works just on speakers and he also just said to blast it . I wonder if I use earplugs if I would be able to tell easily since everything gets muffled with them .

I’d seen videos of guys positioning paper inside to balance voice coils, or adjusting them in some manner while saving the cones and replacing the spider, Iv seen someone bending the frame of the speaker as a last resort and tweaking it and removing buzzing completely , but it seems most people wouldn’t bother and simply offer to recone and gut everything

Author

I tend to just lay the speaker on it’s back, on a folded up thick blanket to soak up the vibrations. No need to load it into a cab. I’ve got a lead with two croc clips on one end for the speaker, and a jack plug on the other end for the amp. Obviously it’s better to solder the speaker, but for quickness I just use the croc clips and make sure they are gripping solidly.

Cone cry, yes not many people look out for that, but a speaker with bad coil rub will sound horrible and should be tested for. Similarly if the spider support is lifting off it will just make a horrible rattling noise.

Yes, I would use the 40 watt amp if that’s all you’ve got. Just be careful with it, obviously don’t dime it fully. 10 watt likely not enough power.

Regarding seeing the cone move, that’s just my rule of thumb when testing vintage speakers. With newer speakers like a heritage G12H you will probably find the doping is a lot stiffer, it can take time to ‘break in’ the speaker and get the cone moving more fluidly. They don’t come from the factory like that.

Regarding repairs I would not recommend bending the frame, that sounds like a recipe for disaster. It really depends on what is causing the rub. Sometimes it is just a bit of dirt in the coil gap. That can usually be cleaned out fairly easily just by removing the dust cap and trying to remove any debris in there. You only need to use the card shims if the coil needs to be repositioned. That would likely involve reglueing at the spider support too. If the coil really is damaged or warped out of shape then the card shims wont help you, it would need a recone, or a speaker repair genius who can replace just the coil and nothing else.

What is your location? Are you in UK?

Iv also seen it mentioned , if you tap on the cone, a healthy speaker will have a some what deep resonance, kind of like a basketball. And if it has issues , it will sound thin and papery, almost like a brown paper bag being tapped .

These two also have this type of resonance when the rest (6 other speakers ) dont . The two definitely scrape when the others don’t aswell. I tried again today to discover any audible issues by playing the rather loud, I haven’t noticed much of a difference , other than one of the speakers in question being about 2 db quieter (I have a db reader) . At one point I heard a lot of rattling when I was playing but the issue was I realized it could have been a metal cabinet vibrating next to a bad so I moved it and wasn’t positive if it was that.

I wonder if once they break in more and get looser, the coil rub will show itself more obviously . It’s definitely there upon inspection with my hands and listening to that , but playing loudly hasn’t revealed a ton for me. I did wear earplugs . I may try and get a sound generator . I just don’t want these two to become an issue in the future under real world circumstances (live/recording) .

Unfortunately I’m in the USA

Author

Sounds like they are borderline to me. You could carry on using them until the rub becomes more noticable. Personally I would just make the decision that they are imperfect speakers and move on. Sell them and replace with some better ones.

I’m sceptical about the tapping on the cone thing, I would like to know what the science is behind that one, but if it works then go with it. Yes the rub will likely become more obvious as the doping loosens up in my opinion.

Coil rub can show up in all kinds of ways. So long as you are using enough volume, it will usually show up when you play some power chords on the lower strings. You’ll hear it buzzing or rattling. However, sometimes it does only show up on certain notes, this is why I recommend to play a chromatic scale and cover all the notes on the fretboard. If you can cushion the speaker somehow this should help to eliminate vibrations through the floor at least. Apparently rubber is best for absorbing speaker vibrations. I normally use a rolled up blanket though.

Brian.

HI Brian,

Love you site, and all the information. I just received a pair of 1972 G12H Greenbacks. One arrived perfectly intact, but the other had the faintest amount of rub. I was able to use gentle downward pressure on the edge of the frame which seems to have eliminated that rub, however the speaker does rattle with low frequencies. I pulled the speaker from the cab and inspected it carefully. The spider is coming up in multiple places. What is the best way to repair this?

Thanks!

Frank

Author

Hi Frank, sorry for the late reply. Someone else has just asked me this same question so I’m just going to copy and paste… It depends on how much of the spider support is lifting off. When only a small amount of the spider support is lifting off, you can usually just glue it back down. A bit of contact adhesive usually works, and weight it down with something whilst the glue sets.

However if a large area of the spider support is lifting off, say 40% or more, then it’s usually a bigger job. That’s because the glue at the edge of the spider support is the only thing holding the voice coil in it’s correct position. So when that glue has failed, the voice coil need to be re-positioned. If you glue back the spider with the voice coil seated at the wrong angle, it will rub. We are talking about fractions of a mm here. The coil gap is very thin and does not allow for much deviation from being in perfect parallel with the center of the magnet.

To do that you would need to remove the dust cap, re-shim the voice coil (I normally use a double layer of 35mm camera film as shims), then apply the glue. However, unfortunately what tends to happen is the glue is so corroded underneath the spider that fragments of it get into the coil gap whilst trying to repair it. This can be a problem, and some people resort to removing the whole cone to clean it out properly. Thesedays I try to avoid doing that whenever possible because it can alter the sound of the speaker.

This is why it is important to always check the spider support on a vintage Celestion before deciding their value when either buying or selling. Repairing speakers in poor condition is not always possible to do successfully, and that speaker you decided was a holy grail collector’s piece, can easily turn out to be worthless. That’s not aimed at you particularly, but anyone else that might be reading, just be aware that condition is everything with them when it comes to their value, and faults like this are very, very common.

I would recommend taking it to a pro speaker repair place if you are not confident doing the repairs yourself.

Hope that helps, Brian.